Harnessing Edge AI Technology in Automotive Manufacturing

The integration of Artificial Intelligence (AI) in automotive manufacturing is not a new concept. However, the shift towards the Edge where AI algorithms operate on the data generated at the source rather than being sent to a centralised server, is a game-changer. In this article we explore the main challenges of embracing Edge AI and why moving AI to the edge brings unprecedented levels of efficiency, safety, and sustainability to car manufacturers.

Keeping Pace with Automotive Innovation

Digital transformation is reshaping the landscape of manufacturing across all sectors, with the automotive industry at the forefront of this change. As we advance into the maturity and broader adoption of the "Industry 4.0" era, integrating AI into automotive manufacturing processes has become essential for operational enhancement and sustaining competitiveness.

The Evolution of AI in Automotive Manufacturing

The integration of Artificial Intelligence (AI) in automotive manufacturing is not a new concept. However, the shift towards Edge AI - where AI algorithms operate on the data generated at the source rather than being sent to a centralised server - is a game-changer. This transition is enabling real-time data processing and decision-making, crucial in a fast-paced manufacturing environment.

Industry 4.0 aims to revolutionise manufacturing by utilising data from a wide array of sources to instantly optimise production processes. This initiative requires precise monitoring and control, relying heavily on the analysis of vast quantities of data. Machine learning (ML) is pivotal in making well-informed decisions from these insights.

.jpg)

The Emergence of Edge Computing and AI in the Automotive Sector

Handling increasing data on-site with edge technology facilitates immediate insights essential for advanced applications such as computer vision, predictive maintenance, and AI in car manufacturing.

Modern car manufacturers are finding new ways to leverage their sensor data. Smart manufacturing is powered by technologies that capture and analyse data generated at source — known as the edge — for better insights and enhanced efficiencies.

Edge computing’s capability to support vast networks of internet of things (IoT) sensors, as well as deliver faster inputs for decision-making compared to the data centre and cloud, are key drivers behind the emergence of Edge Computing in the Automotive sector.

Currently, this involves harnessing artificial intelligence (AI) and machine learning (ML) to analyse vast data sets and deliver insights almost instantaneously at the juncture of data generation and utilisation.

The influx of edge data, while promising, can challenge transformation due to its volume and variety, increasing the demand for real-time insights. Despite this, manufacturers excel by leveraging AI and ML to efficiently process and derive value from this data at its source.

Why Edge AI?

Edge AI significantly enhances automotive manufacturing by bringing intelligence directly to the manufacturing floor.

It enables real-time monitoring and decision-making, improving efficiency, quality, and safety. For instance, Edge AI can predict equipment failures before they occur, reducing downtime and maintenance costs. It also plays a crucial role in quality control, where it can instantly detect and address defects in manufactured parts, ensuring that only products that meet the strictest quality standards proceed down the line. Additionally, Edge AI optimises energy consumption and reduces waste, contributing to more sustainable manufacturing practices. By processing data on-site, it eliminates the latency associated with cloud computing, facilitating faster responses to dynamic manufacturing conditions.

Expansion of Edge AI Applications

1. Equipment Monitoring and Maintenance. Preventing Breakdowns with AI

The affordability of industrial sensors has unlocked vast data pools, enhancing maintenance efficiency through AI. AI-powered predictive maintenance utilises sensor and IoT data to precisely identify maintenance needs, streamlining technicians' diagnostic efforts and enabling proactive prevention of equipment failures. This proactive approach ensures optimal equipment performance, enhancing worker safety, minimising disruptions, and cutting maintenance expenses.

2. Improving Production Quality

AI monitors incoming parts and the production process, using computer vision to automate inspection and instantly identify defects. This allows for real-time correction, avoiding the production of defective goods.

3. Enhancing Worker Safety

AI-driven computer vision ensures machinery is used safely, alerting to improper use of personal protective equipment (PPE) or deactivating dangerous equipment, thereby preventing accidents.

Today, AI's role has expanded significantly, becoming essential in boosting efficiency across production, maintenance, R&D, and more, thanks to its continued technological advancements illustrating its indispensable value in the automotive industry.

.jpg)

What are the barriers to adopting Edge AI in this sector?

The adoption of Edge AI in the automotive industry faces several barriers. One of the primary challenges is the significant initial investment required for the necessary hardware and software, as well as the integration with existing systems. Additionally, there is a notable skills gap; the workforce needs training to effectively implement and manage Edge AI technologies. Concerns around data privacy and security also pose a challenge, as automotive manufacturers must ensure that the vast amounts of data processed by Edge AI are protected. Lastly, the complexity of coordinating Edge AI with existing IT and operational technology (OT) systems can be daunting, requiring substantial time and effort.

Know more about : Scaling Edge AI in Manufacturing

The Challenges of Edge Adoption

While edge computing offers significant benefits for automotive manufacturing, including improved business outcomes, it also introduces distinct challenges.

.- Security in Edge Computing

Edge computing demands a unique security approach, distinct from traditional data centres or cloud models. Ensuring the safety of edge devices and networks necessitates data encryption, authentication, measured boot, and access control.

Securing information storage, access, and protection becomes paramount. The edge offers a strategic option for consolidating and securely managing data at its source, processing, and analysis points, mitigating risks associated with decentralized data centres and cloud environments.

.- Managing Edge Complexity

The inherently complex, highly distributed nature of edge computing, potentially involving thousands of devices across numerous locations, requires automation, orchestration, and standardization for efficient management and application lifecycle maintenance.

.- Upholding Data Integrity

Maintaining data security, privacy, and governance to meet regulatory standards and pass audits is crucial for manufacturers. Edge solutions must guarantee data integrity and comply with local laws.

.- Integrating Legacy Systems

Automotive manufacturers often rely on legacy embedded systems that need ongoing support, even as new edge-native applications are developed and deployed.

.- Continuous Real-Time Monitoring

To ensure operational continuity and timely maintenance, businesses must constantly monitor process and equipment health, without adding to staffing or IT management costs.

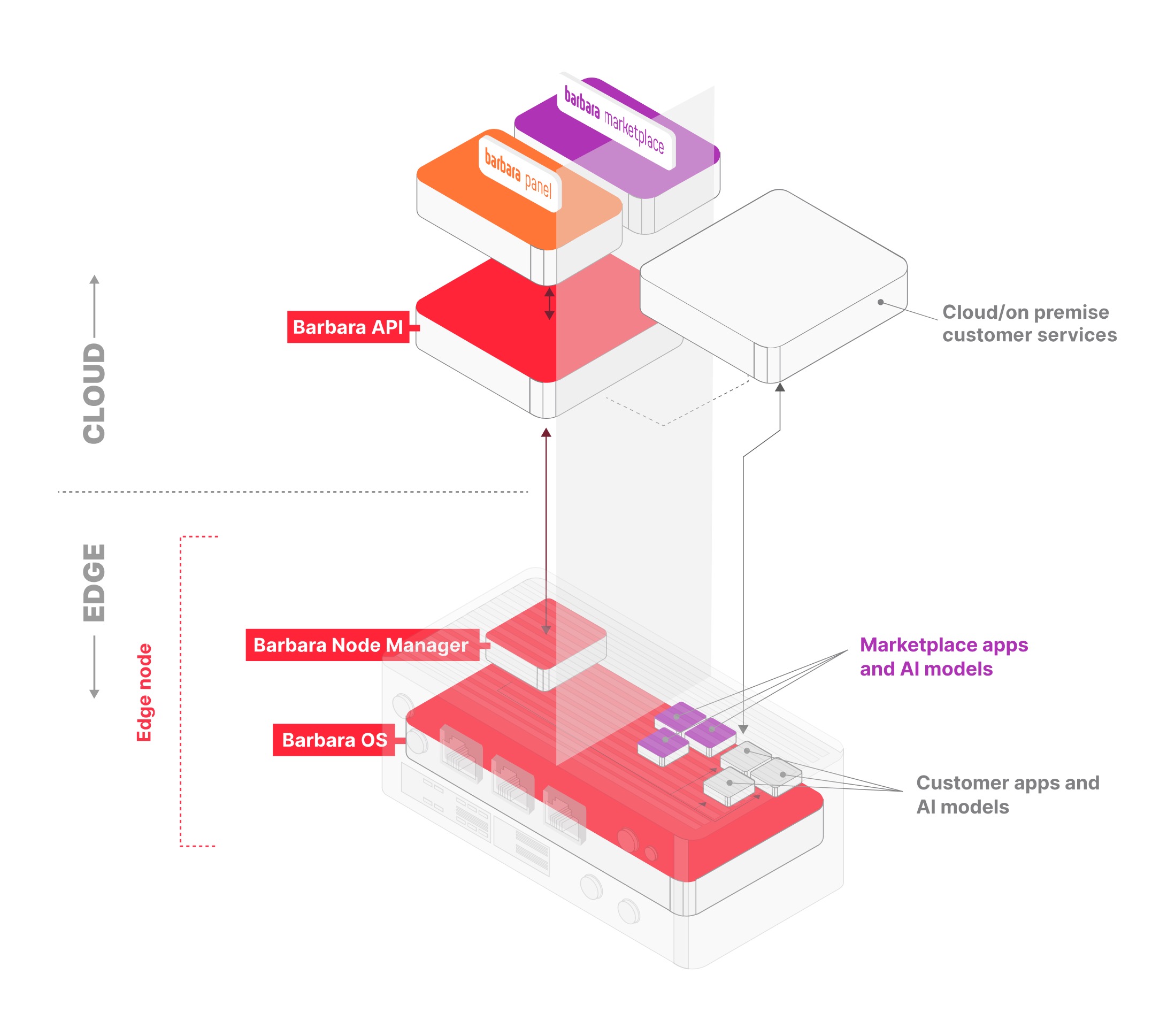

Barbara the Industrial Edge Platform for scaling AI in the Edge

Adapting to data growth at the edge is crucial for the evolution of smart car manufacturing, which aims to position more technology closer to the point of use. This shift requires deploying new AI systems and expanding capacity to accommodate various sites and applications. Physical space constraints in diverse settings, from closets to vehicles, necessitate scalable systems that don't significantly increase the IT footprint.

At Barbara we help organizations manage and orchestrate distribuited edge computing nodes. We are at the forefront of the AI Industrial Revolution. With cybersecurity at heart, Barbara is the Edge AI Platform for organizations seeking to overcome the challenges of deploying AI, in mission-critical environments.

With Barbara companies can deploy, train and maintain their models across thousands of devices in an easy fashion, with the autonomy, privacy and real-time that the cloud can´t match.

Want to start deploying your apps and AI models in the Edge? Start now with Barbara. Get access to a free trial now